Challenge

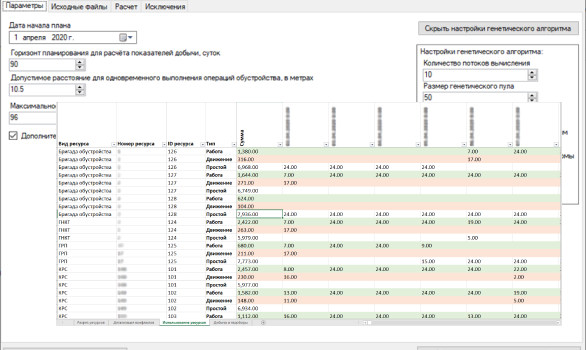

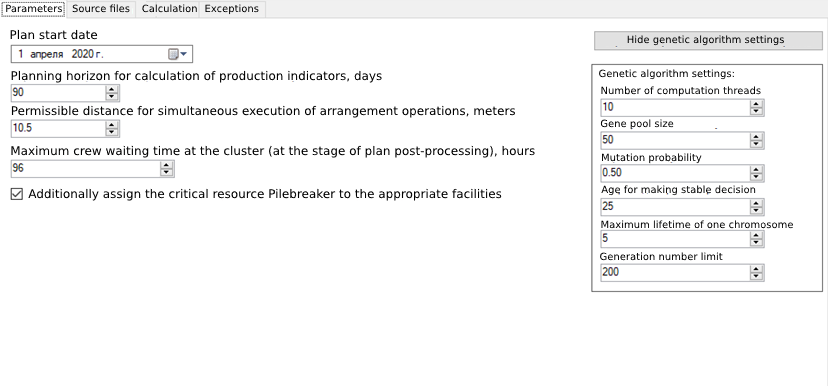

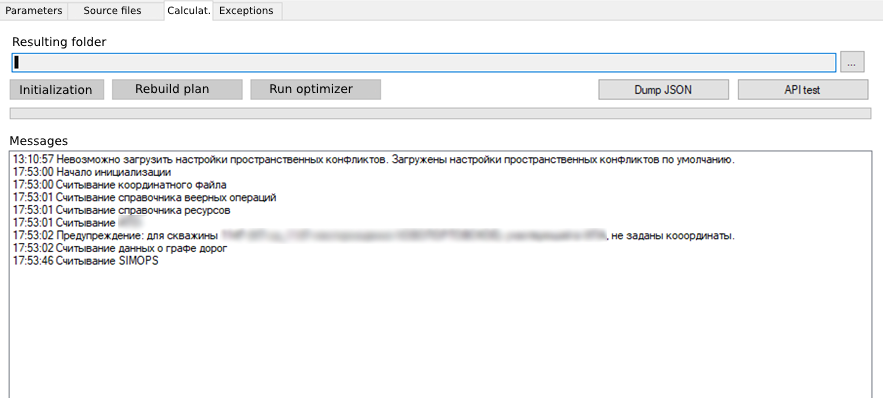

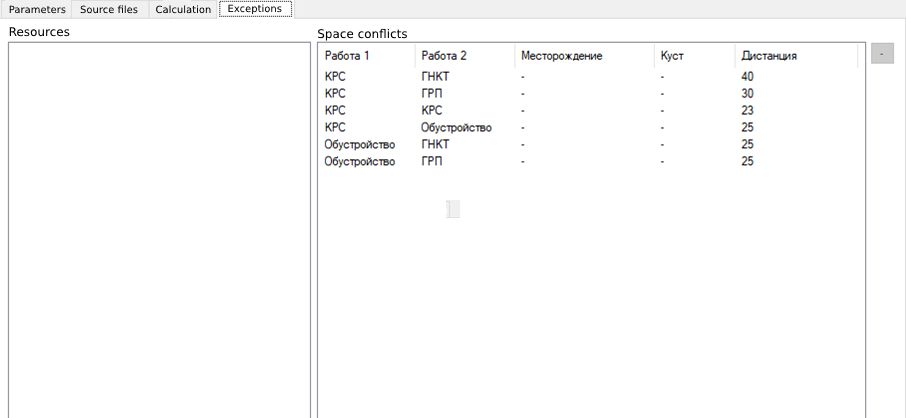

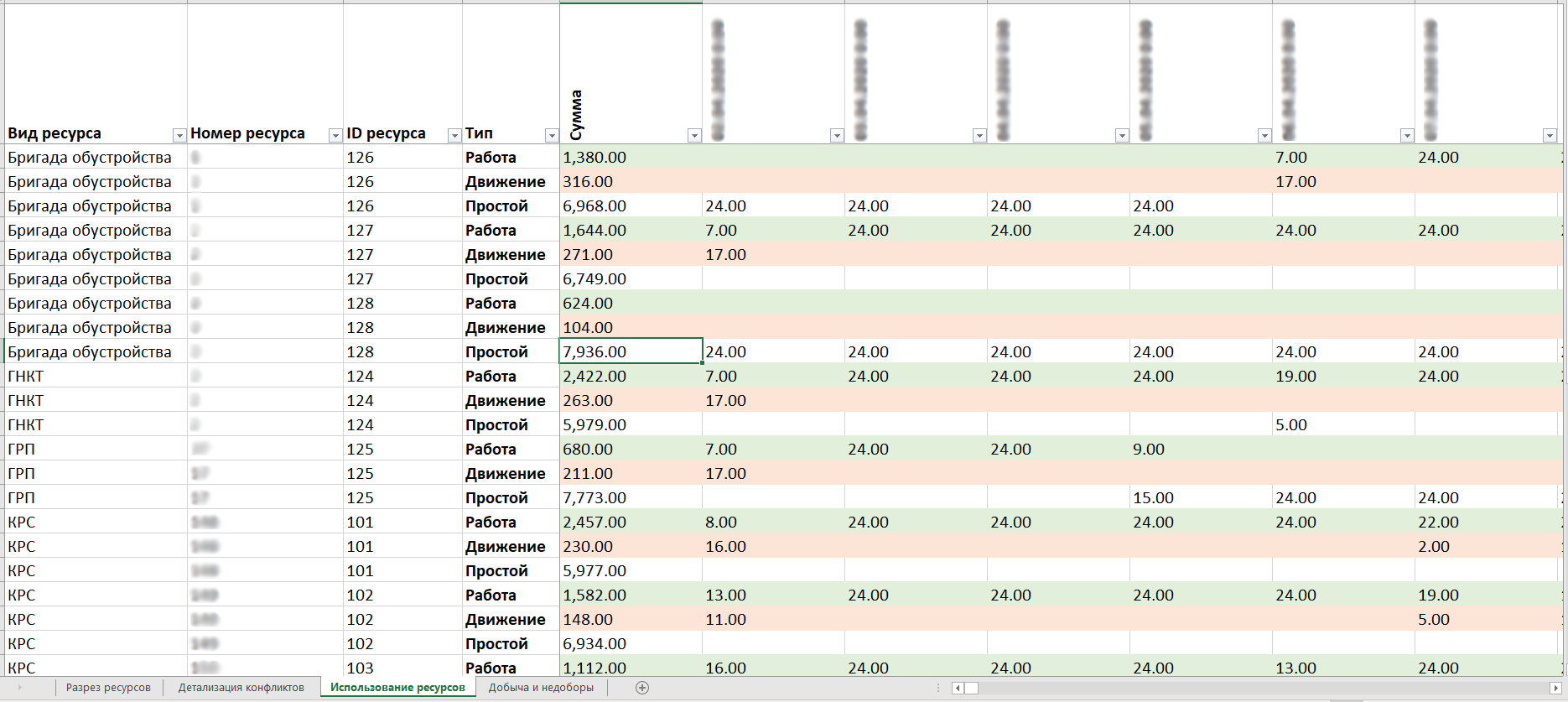

The system was developed for specialists in a large oil company in charge of oil well exploitation and maintenance planning. Before the system implementation, specialists had to do all the operation planning manually, from oil field prospecting to starting extraction operations. Very often the initial plan contained lots of conflicts: one and the same resource was allocated to several operations, time necessary for working teams to get to their working site was overlooked, incompatible operations were planned at the wells at the same time, etc.

Detection of these conflicts and calendar and resource replanning with further verification were not automated. This required a lot of time and effort. Besides, the human factor was not reckoned with: it was hard to detect all conflicts when there were tens and hundreds of planned operations.

But even if a conflict-free plan was produced with all due consideration for all specified restrictions, there was no guarantee it was optimal. This plan allowed meeting deadlines in operations while using the available resources. However, it did not provide for maximal oil recovery from the oil field. That is why the company needed calendar and resource planning automation.